Biological fermentation is an important basis and guarantee for the development of biological economy. Tanlet has a wealthy professional knowledge in the biological fermentation equipment industry, established a strict product quality control system and a strong product R&D system, which can provide customers with scale expansion, process optimization, manufacturing, installation and automatic control system integration services.

Tanlet has the ability to design and manufacture large fermenters, manufacture customized fermenters below 200T (diameter ≤4200mm) in factory. Tanks diameter over 4200mm can be manufactured and inspected at the customer's site.

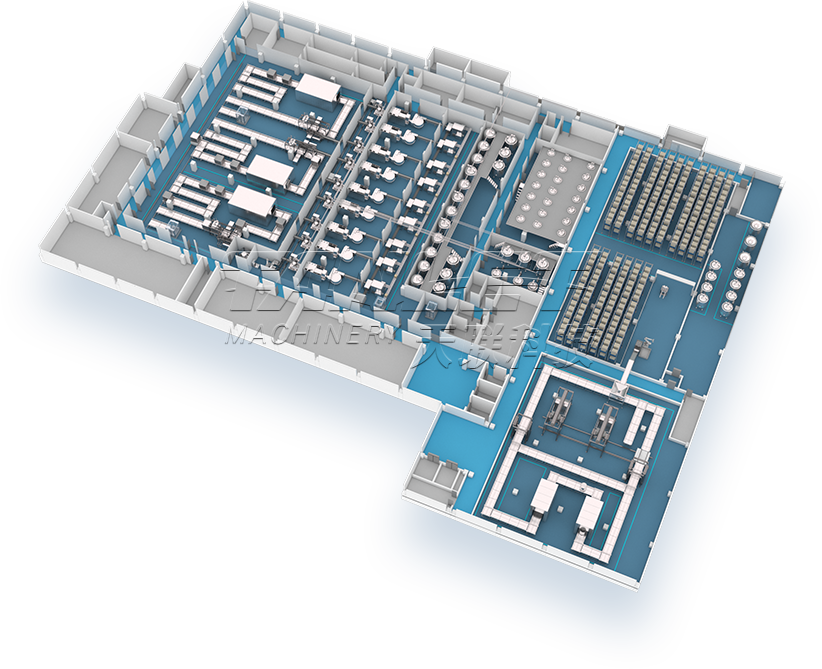

Single equipment and project can adopt 3D visual modeling design to perfectly match the architectural design of the customer's factory. At the same time, by integrating and absorbing advanced fermentation process and mechanical design concepts from Europe and the United States as well as automation control technology, we can provide users with the experience and technical ability of turnkey fermentation project of the whole plant

Antibiotics: Penicillin, cephalosporin, erythromycin

Biopesticide: abamectin, validamycin, gibberellin

Vitamin:Vitamin c, Vitamin B2, Vitamin B12

Amino acid:GMP、IMP

Organic acid: Citric acid, lactic acid, gluconic acid, Itaconic acid (succinic acid)

polyhydric alcohols:Erythritol, xylitol, butanediol

Enzyme preparation:Saccharifying enzyme, amylase, cellulase

Polysaccharide:Xanthan gum, gellan gum, hyaluronic acid

Functional fermented product:Coenzyme Q10, astaxanthin, glucosamine

blood products and vaccines

Traditional fermentation industry: brewery and food industry, antibiotics, amino acids, nucleotides, organic acids, microecological preparations, biological pesticides, biofertilizers, Bio-based chemistry to replace the bulk of the petroleum industry

Modern fermentation industry: Genetically engineered drugs, cell-engineered drugs and vaccines,