This equipment is commonly used reaction equipment in the field of raw materials and pharmaceutical intermediates, fine chemicals, environmental protection, etc.

It is a kind of equipment that mixes twokinds (or more kinds) of liquids and solids of certain volume and promotes theirchemical reaction by using the mixer under certain temperature and pressure. itis often accompanied by heat effect. The heat exchanger is used to input theheat required or move the heat produced out. The mixing forms include multi-purpose anchor type or frame type, so as to ensure even mixing of materialswithin a short period of time.

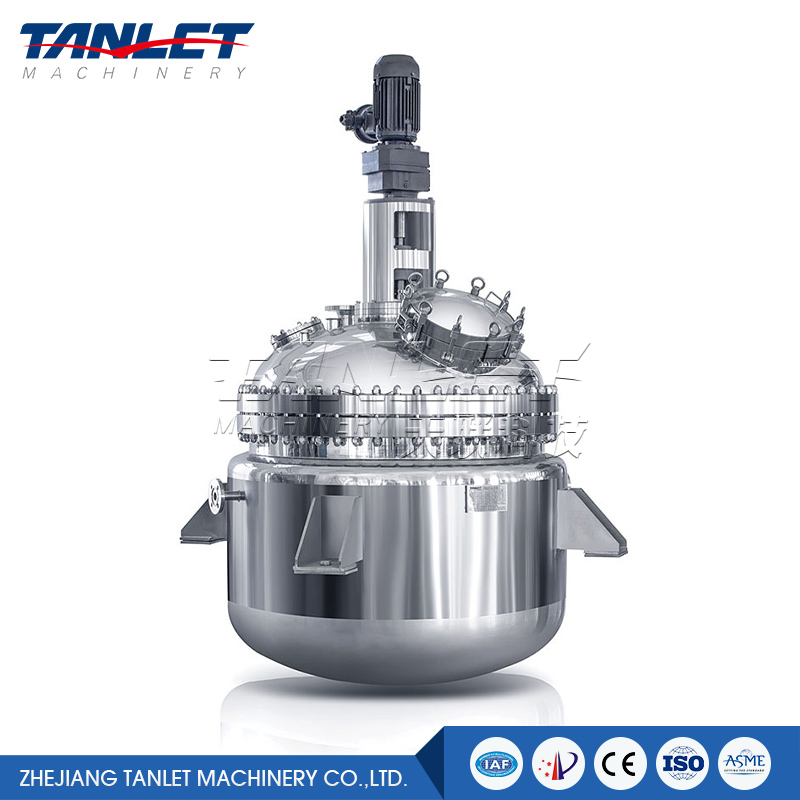

This equipment is made up with tank body, top and bottom ellipse head, agitator, jacket, Supporting and driving device, shaft seal device, material and nozzle could be customized.

Heating media or cooling media into jacket for heating or cooling material inside tank.

Working pressure: atmospheric pressure or negative pressure

The material reacts in the reactor, and the evaporation and reflux of the reaction solution can be controlled.

After reaction, material be drain from the outlet.

Advantage: Automatic plasma or welding by experienced welder

Make sure the material well mixed.

Biopharmaceutical grade water grinding polishing process

Widely used in apis and pharmaceutical intermediates, fine chemicals, food, pesticides, scientific research and other industries, is used to complete vulcanization, nitrification, hydrogenation, alkylation, polymerization, condensation, crystallization and other chemical processes