Born for energy saving. Adopts the principle of waste heat recovery, changes the linear logic of the past evaporator, and realizes the closed cycle of energy: the heat source is no longer provided by steam, but uses the Carnot cycle to absorb and reuse the heat in the evaporated solvent;

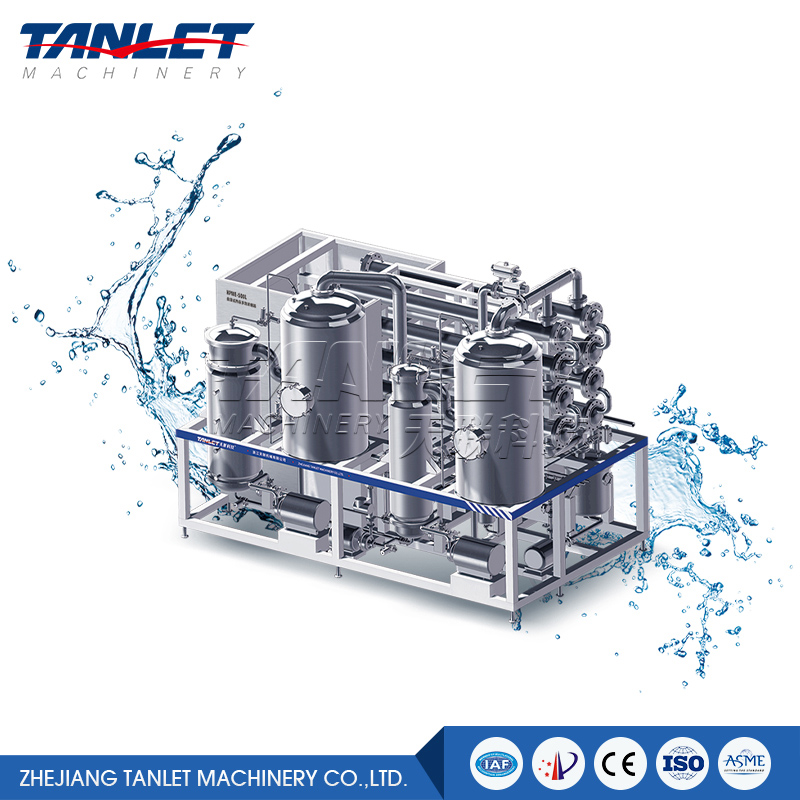

This equipment is made up with electric evaporation module, preheater, condenser, evaporator, evaporation chamber, vapor-liquid separator, receiver tank, compressor, pump and connection spare parts.

The energy released and absorbed by the compressor driving the refrigerant in the closed cycle process is used as the energy required for raw material evaporation and secondary steam condensation, the energy released when the refrigerant condenses is used as the energy absorbed when the raw material evaporates

The energy released when vapor condensing is used for refrigerant evaporates energy.

The system continuously carries out thermal cycle through refrigeration working medium to achieve evaporation of raw materials and condensation of vapor.

In the whole process, the refrigerant and material in the system can fully utilize each other's energy through phase transformation, and realize the concentration of material and liquid, solvent evaporation and solvent recovery.

Energy-efficient: Low temperature negative pressure evaporation , suitable for heat sensitive material

Safe Instead of compress the steam: Compressor compressed the refrigerant for heat exchange with the material. Explosion proof, interconnected control.

Intelligent module Intelligent integrated design, automatic operation; Operation parameters, process parameters monitoring; Skid-mounted module integrated design, occupy small space.

Mainly used in aqueous solution and organic solvent: such as ethanol, methanol, ethyl acetate, acetone, n-hexane solution evaporation and recovery; Widely used in biopharmaceutical, chemical, food dairy and other fields